Team Cockpit Introduction

Please read the Basic Concepts section before starting with Team Cockpit configuration.

Team Cockpit is a component of the 24Flow suite. The Team Cockpit shows an overview of all work (i.e. operation routings and underlying operations) available for a certain team, workstation, operator or machine. Typically this work is separated into three different tables for each Team Cockpit: Expected, In Buffer, In Process.

Expected: The work is currently in process in the previous routing step.

In Buffer: The work is waiting to be started and if possible* can be claimed.

In Process: The work is ongoing.

* More on this in section Team Cockpit and WIP control mechanisms.

For each operation, the operator can be guided with in-context and on page components like time registrations, quality checklists, component picking, work instructions and files.

Team Cockpit, the ERP system and Order Pool

As explained in the documentation of the 24Flow Order Pool, 24Flow expects to retrieve the routing information, i.e. the sequence of processing steps and their respective duration. In case the routing information is not available in the ERP system, it can be configured and maintained within 24Flow.

24Flows uses operation routings for each routing step, i.e. processing step, of a production order. An operation routing will coordinate how the work will move through the factory floor as it provides a link between the current team and the next team. An operation routing can consist of one or more operations that need to be finished. Each operation routing will go to a certain Team Cockpit. The first processing step will be shown in its relevant Team Cockpit once the production order has been released from the Order Pool. Once visible, the operator can claim the operation routing and start working on that particular production order. Once finished, the operation routing will disappear from the Team Cockpit and the next operation routing of that production order will be visible in its relevant Team Cockpit.

The following information is present on an operation routing:

Production Order

From

To

Sequence

Predecessor: The previous operation routing in the routing. Not filled in if the operation routing is the first one.

WIP Control System

Time Required From To (minutes): Capacity / Time that this flow will take from the next team.

Status: The status of the operation routing. Default available status values are (can be extended with custom status values):

INIT: The previous operation routing has status INPROCESS or, if the operation routing is the first one in the routing, the production order is not yet released from the Order Pool.

EXPECTED: The previous operation routing has status INPROCESS.

INBUFFER: The previous operation routing has status DONE or, if the operation routing is the first one in the routing, the production order has been released.

INPROCESS: The operation routing has been claimed.

DONE: The operation routing is finished. Finishing the operation routing can be set for example by time registration or via the Release button in the Team Cockpit.

Work From Team Released: All work of the from team is released from the Order Pool.

Work From Team Finished: All operations for the from team are done.

Can Release Capacity: The operation routing can release capacity if all the work in the from team is done and the status is claimed.

Can Claim Capacity: Flagged when all From Team operation are released, capacity is available (cards or time) and the operation routing is not claimed yet.

POLCA Cards Required: Number of cards this flow will take from the next team.

Paired Team

Team Cockpit Buttons

Claim: Via the Claim button an operation routing can be claimed. This can be the trigger to claim a certain defined capacity in line with a control mechanism.

Release: Via the Release button an operation routing can be released to the next operation routing. This can be the trigger to release a certain defined capacity in line with a control mechanism.

Team Cockpit and WIP Control Mechanisms

24Flow provides different pull-oriented production control systems that can be linked to production order types, products or processing steps with the goal to reduce throughput times by minimizing the work in progress which minimizes the waiting times.

Kanban: typically relevant for batch production, for example for make-to-stock subassemblies.

ConWIP: easier to implement variant of Kanban.

POLCA: typically relevant for high mix low volume make-to-order production.

POLCA time: typically relevant for high mix low volume make-to-order production when accurate estimated durations for the operations are known.

Team Cockpit add-on Components

The following components are typically used in combination with a Team Cockpit. By selecting a row in the Team Cockpit, these components will show its relevant information to guide the operator.

Time Registration

24Checklist

Component Picker

Digital Work Instructions

24Files

Manual.to

In addition to the above list of components to be used with a Team Cockpit there is also the possibility to add custom flow logic. This is described in the following section.

Team Cockpit Flow Integration

Create your own custom flow logic by adding the “24Flow: Team Cockpit Flow Integration” component to a team cockpit app page. By selecting the relevant operation, the operation record id will be sent to the “24Flow: Team Cockpit Flow Integration” component and the relevant Flow.

In order to configure this component, the following input fields need to be set in edit page:

Flow Name: The API name of the relevant Flow.

Hide on Finish: If enabled, the component will be hidden when the Flow is finished.

Extra Flow Input JSON: Extra Flow input in JSON format.

Team Cockpit Sorting

The work can be sorted via well known sequencing rules FIFO (First In First Out), SPT (Shortest Process Time First), EDD (Earliest Due Date), ODD (Operation Due Date), a combination of these sequencing rules or via a custom sorting logic dependent on the desired performance goals of the shop floor.

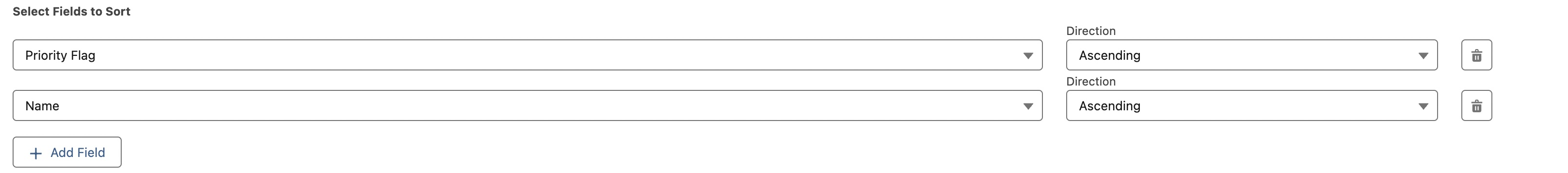

You can add one or more fields to sort by on the Team Cockpit settings page. For each field, choose whether to sort it in ascending or descending order.

Add one or more fields for sorting, taking into account the hierarchy of these fields. Each field can be sorted in either ascending or descending order.

FIFO

+ FIFO is easy to implement (FIFO-lanes).

+ FIFO is easy for the operators.

- FIFO doesn’t take into account due dates and can lead to a bad due date performance.

- FIFO is not a good option for the first operation in a cell, but it can still be a good option for the succeeding operations.

Shortest Process Time First (SPT)

+ Shortest Process Time First minimizes: the average lead time, the WIP and the average lateness.

- Potential long lead times for orders with long PT due to new incoming orders (max. lateness can be high).

- Not suited for components of an assembly item as they need all the same priority.

Earliest Due Date (EDD) and Operation Due Date (ODD)

+ Minimizes the maximum tardiness and maximum lateness.

- Does not guarantee the best delivery performance.

Be aware that the field Sequence which is present on both the Operation Routing and Operation object does not relate to the above described sequencing rules. The purpose of the Sequence field is to order the process steps displayed by the operation routing and operation records for a particular production order.